Custom Product Development

Here at McNeall Plastics we are always striving to provide our customers with components that don’t just meet, but exceed, their expectations. And we know, that sometimes, the ideal component that can do this is yet to exist.

That’s why, in addition to our custom formulation offering, we also provide a custom product development service. So no matter what you need, you can be confident that our team can deliver.

Our product development cycle is a collaboration between our customers and our team and consists of a 6-step process:

Business Case

We prepare a business case where commercial benefits are stated showing savings due to the replacement of the existing product, engineering and test expenses with payback calculations.

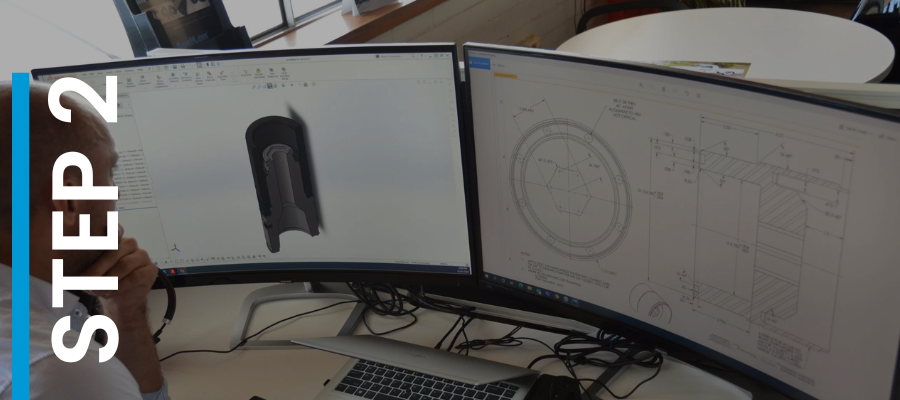

Product Design Review

Structural analysis is performed and product shape can be slightly modified to suit the new material. Design and structural analysis is reviewed and approved by the customer.

Verification Planning

Verification testing protocol is developed & reviewed with customer. Verification testing is performed & documented in a controlled (not production) environment for the customer. Protocol is reviewed and signed off by the customer.

Verification Stage

Actual tests are performed as per agreed protocol and results are recorded as pass or fail.

Validation Planning

Validation protocol is developed & reviewed with the customer. Validation is performed in the production / operational environment with the purpose to satisfy customer with proposed monitored performance characteristics to sign off product for future use.

Validation Stage

Product is used in situ for a certain period. Performance is monitored using performance characteristics as per validation protocol. Results are recorded as PASS or FAIL. If result is PASS, product is signed off for future application.